Organizational Supply Chain Infrastructures

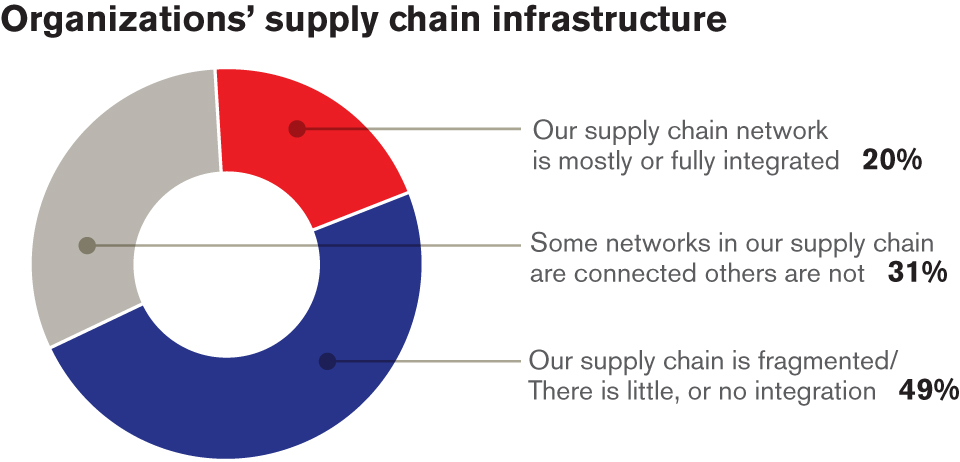

Supply chain integration happens when all stakeholders along the supply chain share the same objective (i.e., move the right product to the right place at the right time for the right price to delight the customer/end user), and are aligned in their efforts to achieve this goal. One out of five survey respondents says that its supply chain is “highly integrated” while another 49% acknowledge that some (but not all) of their networks are linked. Still, another one out of three companies admits that its supply chain lacks connectivity and is either “somewhat” or “totally” fragmented. In the end, a seamless supply chain is better equipped to track the movement of goods, allow operations to better understand inventory levels, forecast demand, and identify, assess, and manage risk situations—all of which help to keep the global supply chain operating smoothly. (Figure 8)

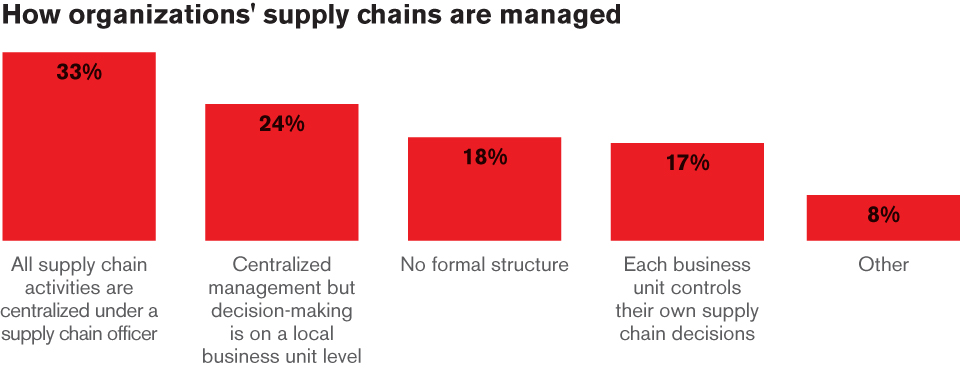

With so many companies grappling with fragmented supply chains, it’s no surprise that the majority of firms manage their networks with little structure or organization. In fact, only one out of three shippers has a centralized supply chain, where a top supply chain officer heads up the operation. More than four out of 10 companies operate more decentralized supply chains with the various business units shouldering decision-making duties; interestingly, almost one out of five supply chains lacks any structure at all. (Figure 9)

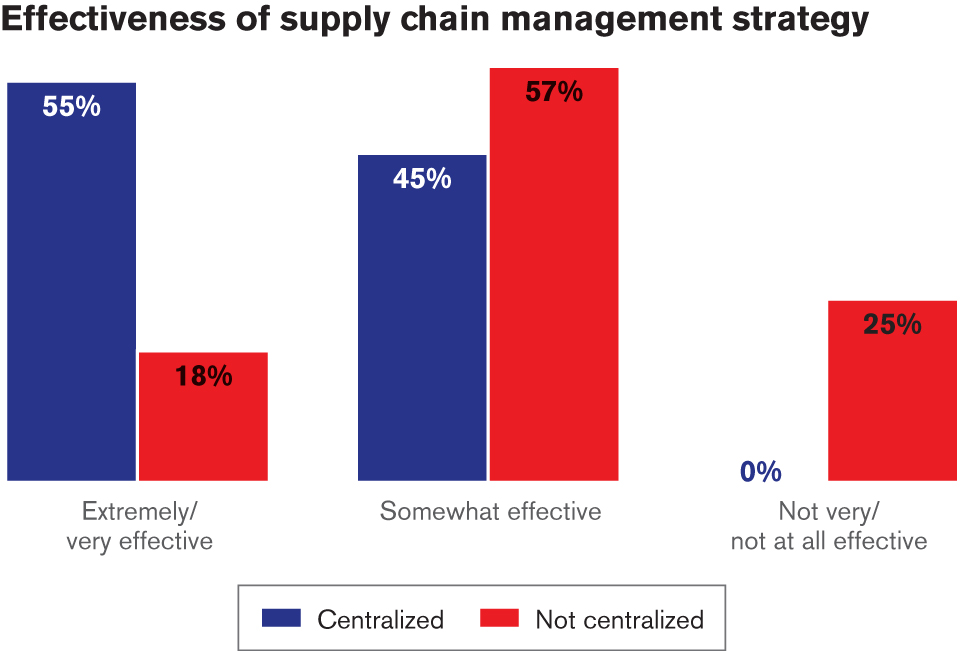

Regardless of how they’re managing their supply chains, supply chain managers are moderately satisfied with their current strategies, suggesting that many supply chains could operate more efficiently. However, those managers that are operating a centralized supply chain feel that this approach is more effective than those networks that are decentralized. As with any business initiative, the more fragmented the responsibilities and tasks are, the more opportunities for improvement exist. (Figure 10)